Our visit to the Prop Shop

By Vance Jaqua with Jim Mendrala

Our team

Guy and Peter, waiting to ferry us to lunch

|

PIC: Don Dawson

|

Still hard at work on our flyable 1903 Wright Flyer replica,

several members of our team travelled to the offices of Guy Watson who

has agreed to carve new propellers for us. The team was shuttled

up to South County Airport near Morgan Hill, CA by Don Dawson in his

Cessna Turbo 210. The trip up went off without a single hitch.

The timing of the flight was almost unbelievably on schedule. The stop

at the Van Nuys airport to pick up the two hitch hikers (Jim Mendrala,

and Vance Jaqua) was seamlessly accomplished. The flight up past all the beautiful,

and desolate area to the destination was rapid, but safely uneventful.

Peter Talbot (our technical contact) and Guy Watson (chief carver) greeted us at the

airport and ferried us to the museum via an excellent lunch stop.

|

|

|

|

|

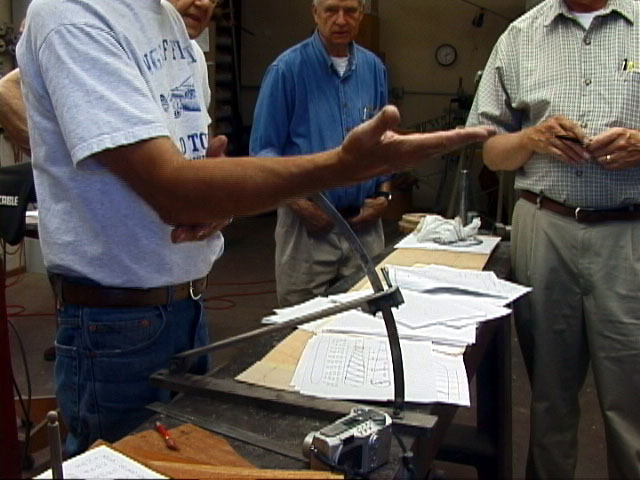

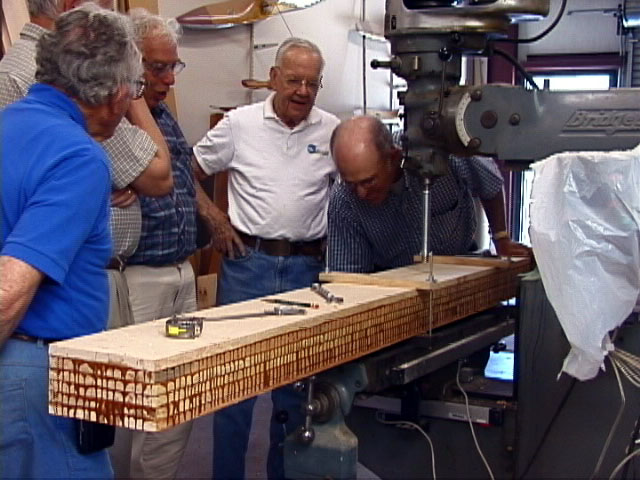

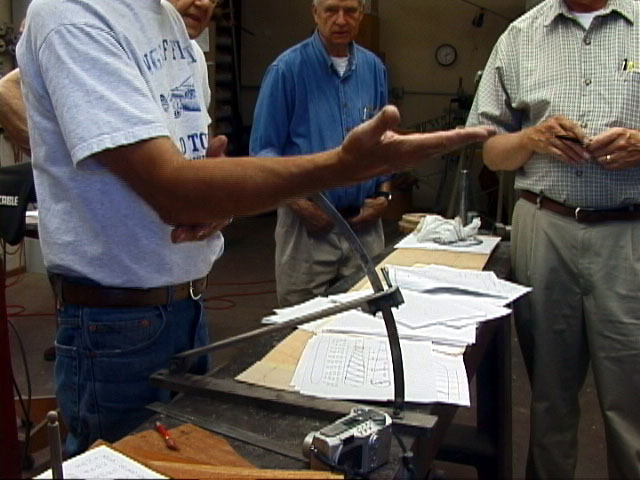

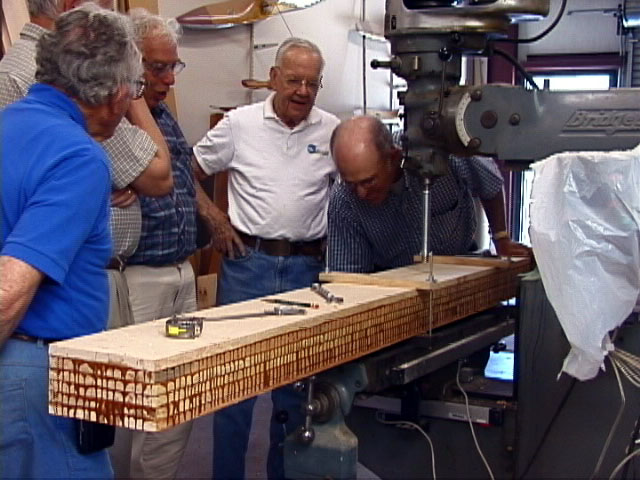

| The technical staff of the prop-shop explaining factors

important to them when carving a propeller. |

The personal interchange with the people that were going to do the work

was greatly productive. It was quickly discovered that the two groups

(us and them), coming at the problem of producing thrust from two

different directions, speak a different language. Even though both

groups have the right idea, a telephone conversation would have led to

trouble. Some errors in the drawings were identified, and fixes

were outlined to correct any confusion and to expedite the progress of

the work.

|

|

|

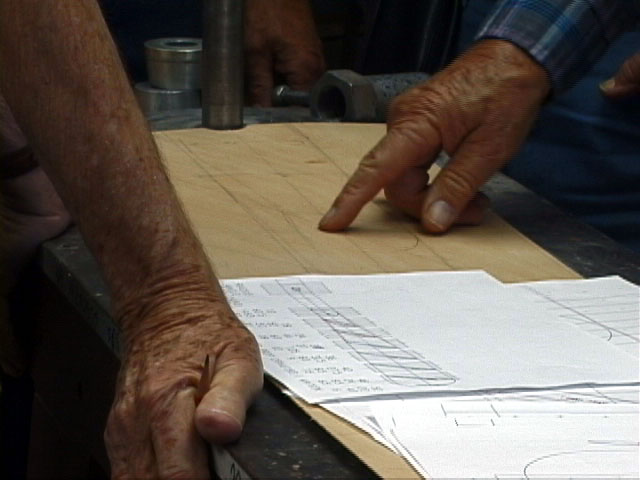

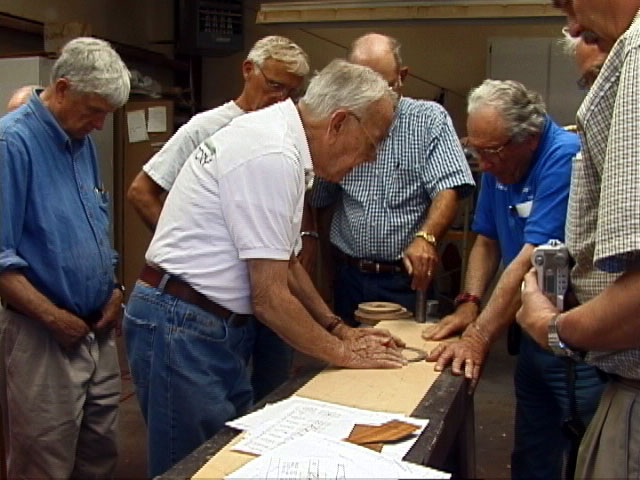

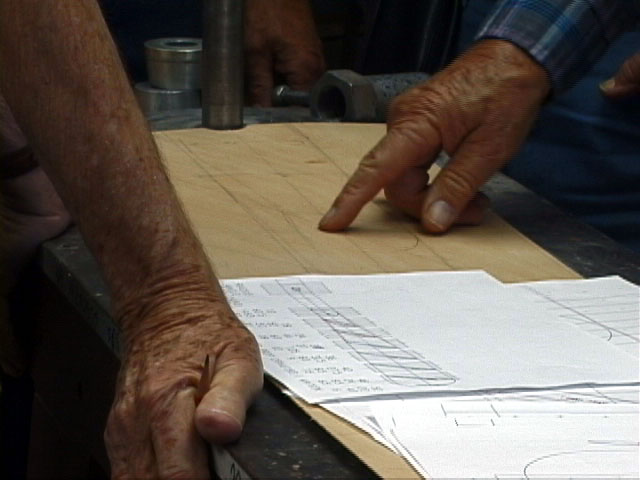

Vance Jaqua, Don Crawford, discuss what is required by the airplane from the

propeller system while project chair Howard Marx listens closely

|

As you can see in the photos a lot of discussion was about the angle of

the wind relative to the propeller, the size of the hub and the width

of the propeller near the hub. Discussions also took place about the

mounting of the propellers to the propeller shaft and the fact that the

two props counter-rotate. The hub configuration on the drive shafts is

considered marginal by

virtually all parties, and design changes have been initiated.

Transitioning from the innermost foils to the rectangular hub is still

in question on detail configuration, but is not seen as problem at this

time and it will be resolved.

|

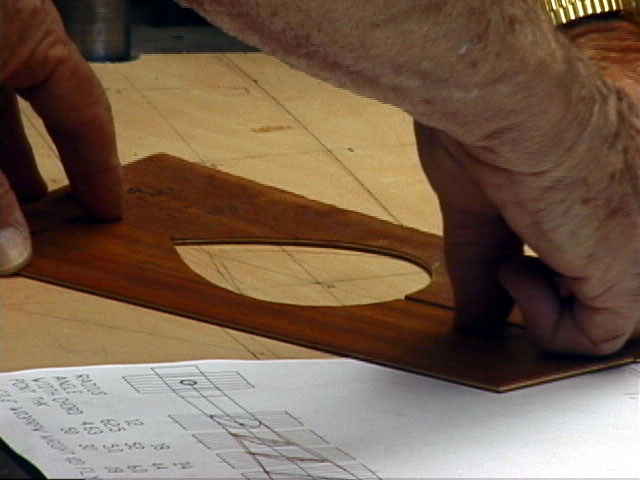

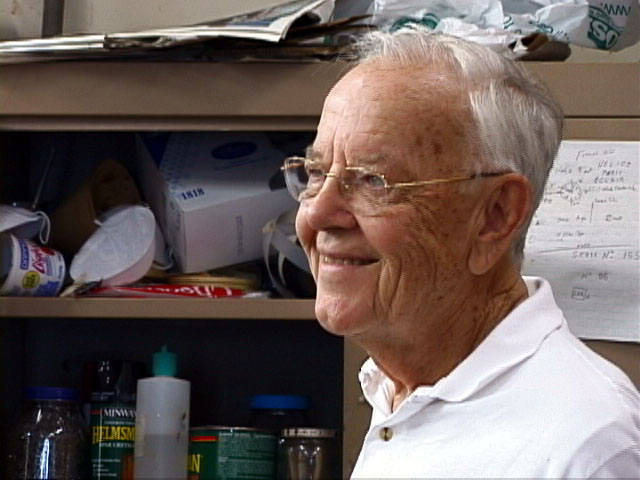

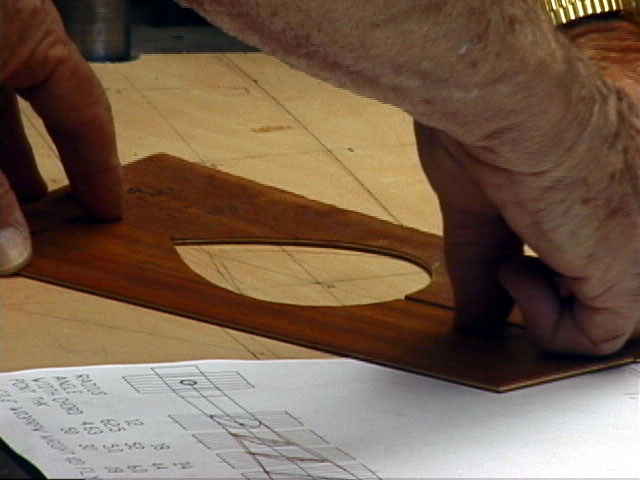

Howard Marx inspecting the trailing edge radius of an existing propeller

|

|

One important factor they at the prop shop reminded us of was that with a wooden prop,

a reasonable trailing edge radius would minimize damage

and make the shaping of the foils much more practical. Don Crawford

accepted the task of recomputing the foil sections to this end, and

Vance agreed to turn those into drawings.

|

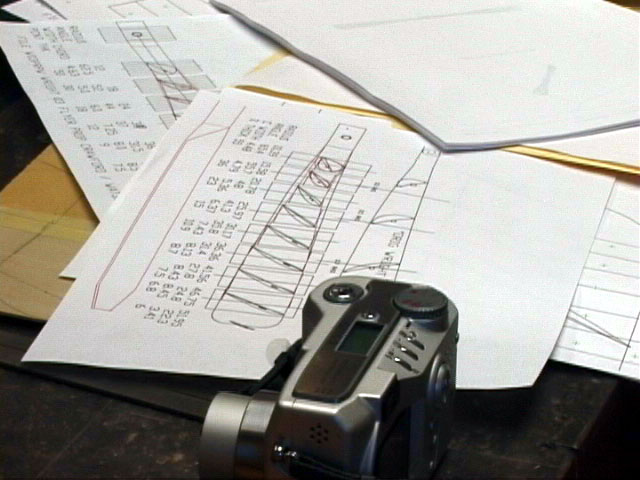

It is interesting to note that wooden propellers are not carved from a

single block of wood, but rather from a laminate - several pieces of

wood laid up and glued together. Guy and Peter showed us a blank

layup that they will turn into a functioning propeller for another

customer, and demonstrated how the laminate construction can be

stronger than a simple solid piece of wood with the help of an

engineering aid.

|

A sample laminate used as an engineering aid for a pull test

|

All too soon it was time to return, and we did not get a chance to

really appreciate the excellent museum. They have acquired a full

scale, non-flying replica of the 03 flyer, and it helped in many of the

discussions.

|

|

|

|

Inspecting the museum's 1903 Flyer replica to make a point regarding the prop hub

|

The return flight, with both Don's in the front seat, was a repeat of

the rapid and uneventful flight up. And though we all overstayed our

"kitchen passes" it was a still too soon close of an excellent and

productive day.

What an absolutely wonderful museum!

In a touching find, Howard Marx spies one of the first airplanes (a glider) which endeared him to the joys of flight

Copyright © 2004, AIAA Wright Flyer Project,

all rights reserved.